Certifications

Fully certified & compliant, we follow industry best practice & processes ensuring continual service quality, safety & negligible environmental impact. We endeavour to deliver projects on programme, in budget and & on time resulting in ongoing customer satisfaction.

Quality Management System

Quality is key to the success of our business. We strive to deliver a first-class service and the best quality products possible to clients, who are our number 1 priority.

We’re certified to ISO 9001:2015 Quality Management System (QMS), an international quality standard.

This helps us to monitor and manage quality levels across our operations so we can identify any areas that may need improvement.

Along with ISO 3834 WQMS and BS EN 1090 FPC – ISO 901 QMS forms part of our fully integrated quality strategy that covers all elements of the business – from the manufacture of products in our fabrication workshop to the final delivery of projects and aftercare.

We’re dedicated to this cycle of continual improvement which is embedded within the business. We always listen to our clients and adapt to their changing needs.

Through lessons learned, we never stand-still and endeavour to exceed the needs of clients so that we can achieve positive feedback and long term customer satisfaction.

Environmental Management System

We’re committed to protecting the environment from any avoidable harm, misuse, or neglect. We believe our current business activities have a limited and negligible impact.

We’re certified to ISO 14001:2015 Environmental Management Systems (EMS), which ensures we follow best practice procedures and processes.

We carefully manage our impact on the environment by following green initiatives to make sure we lower our carbon footprint, maximise recycling, minimise waste and make sensible use of any resources.

We always make every effort to identify all environmental factors that may affect any of our projects. We ensure all parties are fully aware and informed, so that we can manage and control the situation following EMS best practice guidelines..

Occupational Health & Safety Management System

We have an uncompromising commitment to the health and safety of all our stakeholders, especially employees, clients, partners, and the public.

We’re certified to ISO 45001:2018 Occupational Health & Safety Management System (OHSMS) which forms part of our risk management strategy.

We have embedded this standard into our business, to prevent any work-related injury and ill-health to personnel, and to create a safe and healthy workplace – both within our offices and when onsite.

We believe the key to delivering successful projects is by creating a safe and controlled working environment, where staff can thrive and excel.

We take an active approach to health and safety, our H&S Manager conducts regular training of staff and continually monitors of performance.

QHSE POLICY

Welding Quality Management system

We are certified to ISO 3834-2:2021 Welding Quality Management System (WQMS), an international welding standard.

We use this in conjunction with ISO 9001 QMS and BS EN 1090 FPC to ensure we provide high quality welding services, both in our workshop and onsite. WQMS defines the quality standard we need to meet when producing welded constructions in accordance with specified criteria.

The standard is used in addition with testing and places the necessary controls and procedures in place so we can we produce high quality welds, each and every time. It also controls our production process so that it meets a set standard and criteria.

ISO 3834-2:2021 has enabled us to operate more efficiently by decreasing our number of defects, waste, and rejections. This has meant fewer reworks and improved our overall level of quality making sure we get it right first time.

Factory Production Control & UKCA/CE Marking

We are certified to BS EN 1090-1:2009 Factory Production Control (FPC) standard, which allows us to UKCA/CE mark any products we make for the UK and EU.

BS EN 1090-1 is a harmonised standard that covers structural / construction steel and aluminium products that are load bearing and installed in a permanent manner. This falls under the mandate of the Construction Products Regulation (CPR), which stipulates that it is a legal requirement to UKCA/CE mark products to prove compliance to BS EN 1090-1. This is enforced by Trading Standards who have the power close down businesses that do not comply.

As part of this process, we are periodically audited by our notified body, TÜV NORD, to validate our Factory Production Control System.

This proves we conform to BS EN 1090-1, confirming we have the best qualified staff, equipment, processes, and implement the most suitable control procedures. This ensures traceability of every component we use throughout the fabrication process – from initial source to final delivery of finished product.

We are certified to Execution Class 2 (EXEC2) of the standard which allows us to fabricate the vast majority of steel structures in our workshop before delivering them to site fully UKCA/CE marked for final installation.

This demonstrates our advanced skill levels and capabilities when working on the most complex and demanding of projects. It also shows we are fully compliant with structural steel regulations and can prove our final products are of the highest quality, fit for purpose and structurally sound.

Fleet Operators Recognition Scheme

Our transport division runs an extensive fleet of vehicles so we can service clients nationwide. We’re members of The Fleet Operator Recognition Scheme (FORS), a voluntary accreditation scheme for fleet operators.

FORS has nearly 5000 members with over 100K accredited vehicles on the road. It aims to drive up standards and improve quality within fleet operations. FORS demonstrates which operators are achieving exemplary levels of best practice in safety, efficiency, and environmental protection.

We are certified to FORS Bronze level which confirms we employ good practice and comply with requirements within the FORS standard. This includes demonstrating dedication to driver and vehicle safety, combined with improving operating practices through effective monitoring of fuel and tyre usage.

As a company that champions continual improvement, we’re working towards achieving FORS Silver level, before moving on to the prestigious Gold Standard.

FORS acts as a benchmark for us to monitor the quality and performance of our fleet operations. It demonstrates that we are a high-performing operator who seeks to embed industry-leading best practice within its business.

FORS also provides us peace of mind, that we’re managing our work-related road risk (WRRR) and creating a safe work environment for all staff.

Considerate Constructors Scheme

The Considerate Constructors Scheme (CCS) is an independent body created to help improve standards across the construction industry. The scheme is nationally recognised and recommended by local authorities, the government, main contractors, and major industry clients.

We’ve been a registered organisation of the CCS since 2018, company ID 2288.

Companies sign up voluntary and commit to abide by the schemes Code of Considerate Practice. This is designed to encourage a positive working environment and the adoption of industry best practices.

CCS covers three key areas that define expectations. These include Respect the Community, Care for the Environment and Value the Workforce.

Organisations can also register any of their project sites for additional evaluation.

Audited annually by CCS, our level of performance been independently rated as Very Good / Excellent and within the top percentile of UK companies.

Achilles Utilities Vendor Database

We are registered and verified with the Achilles Utilities Vendor Database (UVDB) ID 00020953. This is a supplier management framework for all major UK utility organisations.

UVBD is a standard pre-qualification system for the UK utility industry. It is used to manage risk and compliance with UK regulations when selecting suppliers.

The system allows over 66 utility buyers to qualify the supply chain through a rigorous audit and assessment of supplier’s management systems and onsite performance.

We’re Silver Plus certified which demonstrates our compliance with risk assessment, health, safety, environment, and quality requirements essential for the utilities industry

INDUSTRIES WE SUPPORT

We’ve built an enviable reputation across the industry for the quality and reliability of our work and the strength and depth of our people’s skills and capability. Our core business focuses on the pipeline industries, but we serve a diverse range of sectors.

WHY WORK WITH US?

We’re a well-respected, established company with a vast amount of industry experience having completed hundreds of successful projects over the years, both large and small, covering many market sectors within the UK, Europe, Africa, and Asia.

40+ Years in Industry

Complete Turnkey Services

UK & Worldwide Coverage

Fully Certified & Compliant

Highly Experienced Team

Client Focused Solutions

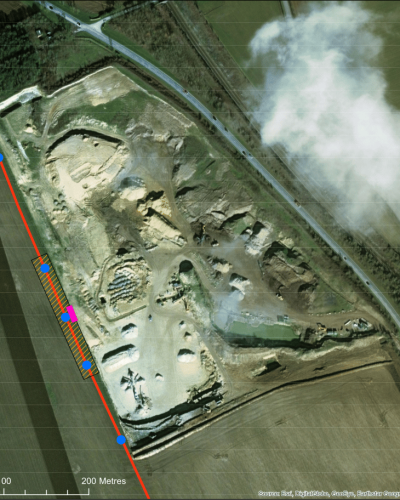

LATEST PROJECTS

Our fully certified and highly experienced team has a strong portfolio of successful projects, both nationally and overseas, including cross-country pipelines and diversions, hot-tapping, AGI construction with prefabrication, installation, and any related civil works.